Here we will introduce the manufacturing process for Zodia's signature product, the soft iron forged club head.

Forged Soft Iron Heads

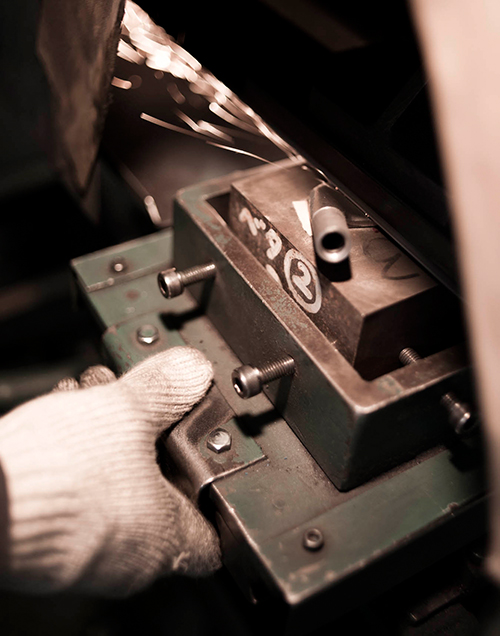

After rough hammering, burrs are removed and the finishing hammering is done again.

![]()

The Club Number is Stamped on the sole.

![]()

Weight Adjustment

![]()

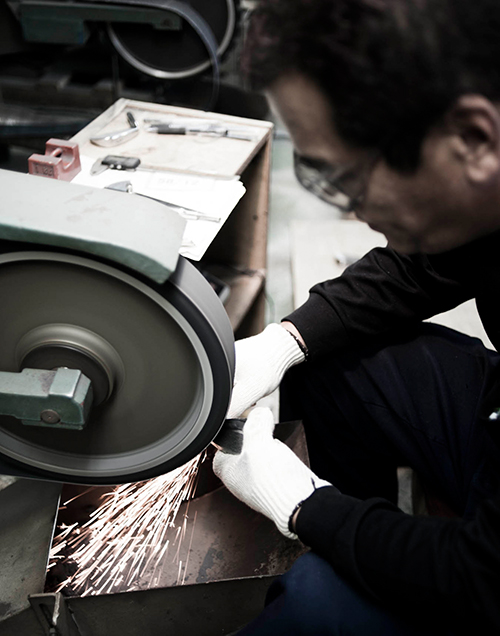

Smooth processing by NC

The face surface, which has been ground with a grinder, is then made even more precisely flat using an NC processing machine.

![]()

Score Line Stamp

Score lines of uniform thickness and width are stamped onto the face, which has been smoothed by machining.

![]()

Loft and Lie Angle Adjustment

Normally, this is done by bending the string, but at Zodia, Chiba adjusts it by hammering, which allows for fine adjustments to the natural curve.

![]()

CNC Processing

The back face design is created using 3D processing.

![]()

Engraving

![]()

Polishing

Chiba's bold and delicate techniques are used to create the Zodia head.

![]()

Completed

The clubs are then painted and inspected for a final finish before being completed. In this way, Chiba personally handles many of the processes and takes a long time to create the clubs, ensuring a quality that cannot be replicated by mass-produced products.